MickMake Meets Robots and Dinosaurs - Part 1: Laser cutters, CNC and other machinery

Mick visits one of Tim’s old school mates, Gavin Smith, who runs a MakerSpace called Robots & Dinosaurs in Meadowbank, Sydney, Australia. Part 1 looks at laser cutters, CNC machines and some old school stories.

Part 1: Laser cutters, CNC and other machinery

Check out Part 2 of this transcript and video.

Transcript

Intro

So, some bozo decided to delete the intro that we did previously.

Yeah, that's right.

Who was that, Tim?

That was the guy holding the camera, because I can't do it. I'm driving.

Oh yeah, right.

So, we're on our way to Robots and Dinosaurs.

Yup, R&D. I've already seen photos on Facebook and the website. I hear they've got some machinery, stuff that you would find really useful, but you wouldn't use too often. So, hard to justify buying.

Also, the space, the garage, you couldn't. Laser Cutters are pretty big I understand. For those people who say a garage is for a car, you're mistaken. Where am I now?

Turn right, yeah. Let's see what it looks like.

Alright, looking forward to it, mate.

Must be upstairs.

On your phone I thought it was just there that way.

If you look at Google Maps, you can actually see it's pointing roughly here. Okay, this is looking promising I think, maybe.

Ten?

Actually it should be ten, yeah.

14. There we go.

Ten. I don't think it's the Australian traditional medicine society. Maybe they've moved. What about this 8B?

No. Have to give him a call.

Hey, mate, I'm completely lost. I'm standing in the parking lot where there's a zodiac.

There he is.

Camera

Laser cutters

This is Robots and Dinosaurs. We are a place where people come together and just make things. We've got a whole bunch of bits and pieces to help with that. Got a pair a laser cutters over here.

Alright.

Nice.

Camera

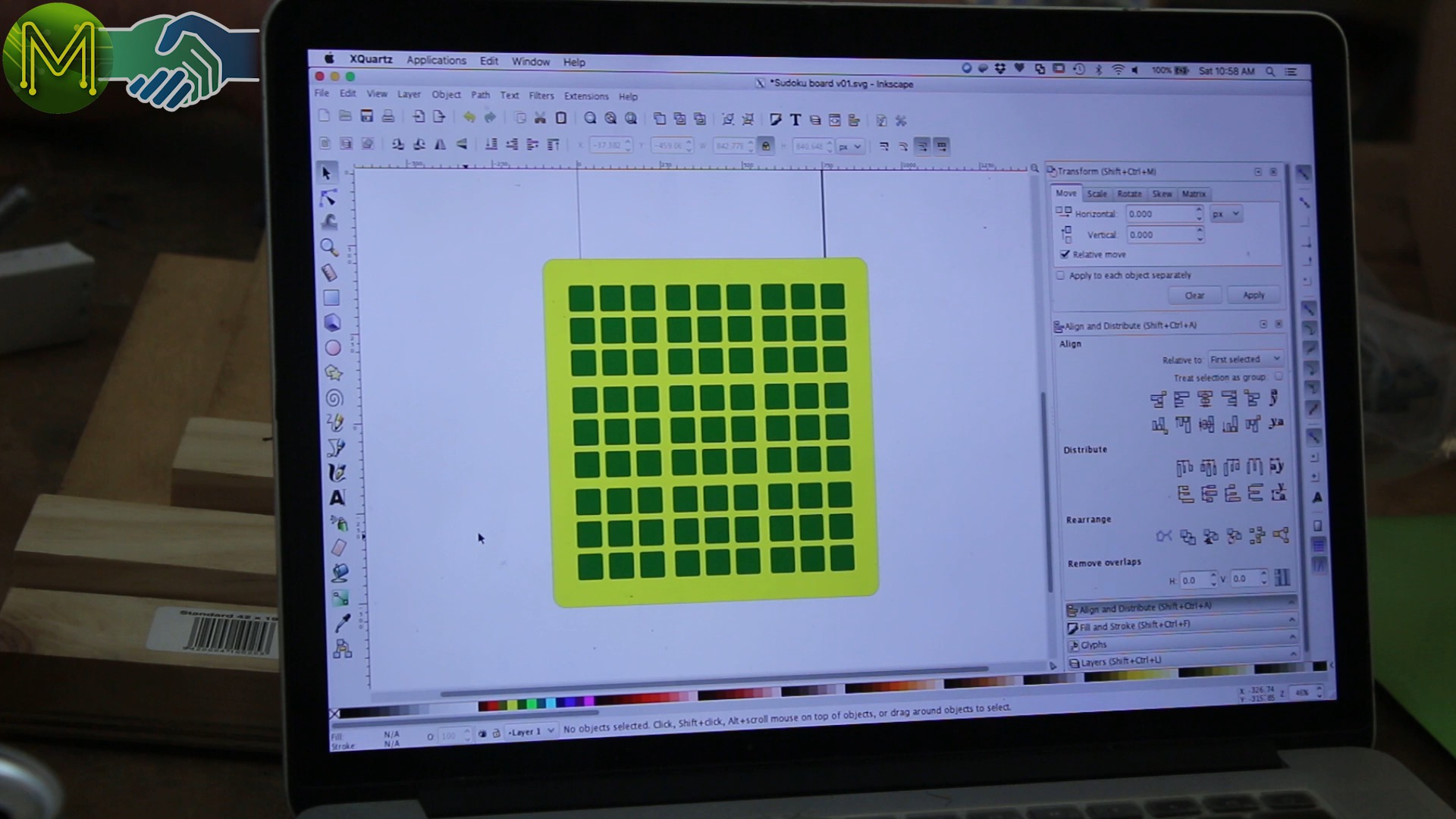

I was actually just playing around making a Sudoku board this morning.

Is this the cutouts from the board?

Yup, just little test pieces at the moment. I'm just playing with the scaling until I get the whole thing.

What material are you cutting?

This is bamboo plywood. We've got MDF as well. It's really easy to cut wood. It's really easy to cut plastic.

Obviously not too thick though.

Yeah, that's it. The plastic you can get a bit thicker. That's quite strong.

That's perspex?

Yeah.

Camera

Magic mirrors

Tim and I had a discussion on the way over. What would happen if we tried to cut a mirror?

See that glass tube at the back there?

Yeah.

That is a CO2 laser tube. It makes an infrared beam. So, have a look at this... Electromagnetic spectrum. You've got blue light here. You've got red light here. Every piece of visible light you have ever seen and enjoyed in your entire life has been within this little range here. The CO2 laser is over here. It's so far away from visible light that what we think of is mirrors and what we think of as transparent doesn't quite apply, which is why you can have a see-through window on the top rather than a totally opaque box.

Camera

The way that you cut acrylic is that it melts and then it runs away through the gap where it vaporizes, so you're locally heating and melting. If you try and cut metal, it's too good at heat sink, so instead of getting one really hot spot that vaporizes and cuts, the whole thing just gets slightly warm.

These mirrors are magic metal of some sort.

Magic metal?

The previous slice cutter we had, copper mirrors. It just polished copper.

Oh, okay. Yeah, makes sense.

That works really well, because it's reflecting off the service, it's really efficient as opposed to a glass metal mirror where it's got to go through a layer and then out again so you're not heating the glass.

Camera

Inside the boxes is activated charcoal plus two layers of filtration on top of that. The idea is to just capture anything that comes out of the laser cutter, so we can be nice neighbors.

Yeah, okay. I saw that coming outside, but no, but then you filtered it.

It's filtered, yeah. This is a commercial filter specifically for laser cutters. This behaves worse than the one we made ourselves, so this is why this thing is disconnected and in the corner. That's pushing in and that's pulling out.

Okay.

There's a third fan inside there as well.

I take it that this second fan has to be more powerful than the blower with the positive pressure.

No, no, it's easier to push than it is to pull because you can push as many atmospheres as you like, but you can't pull more than one atmosphere. If you're pushing water in a pipe up a hill, for example, you can push it as high up as you like, but you can't such water through a straw more than ten meters because ten meters of water is one atmosphere worth of pressure. You'd end up with a perfect vacuum at the bottom, and you can't have a negative pressure.

Acrylic, Plywood, MDF and Bamboo sheets.

Camera

Trying not to kill yourself

Yeah. ABS is okay. It's a bit smelly.

One of them puts off cyanide?

PVC.

PVC, yeah okay.

Is it chlorine gas?

Yes, it's chlorine gas.

Chlorine gas.

Polyvinyl chloride - Chlorine gas.

I'll show you how to test that if you got a sec.

Camera

Oh, okay.

This is known as the Blowtorch Test. If you've got a bit of plastic, and you're not sure whether it's laser safe, this is a quick and dirty test you can do to see whether it contains chlorine. If it doesn't contain chlorine that doesn't mean it will cut well, but it just means it won't kill you in one specific way. So, it's a good first step.

Ordinary bit of copper here, and a bog standard blowtorch. Just heating this up to red hot just to make sure there's no plastic left on. We'll dab that in our test piece, and some of the plastic ends up stuck on the tip. Now what I'm gonna do is heat it back up again. If there's chlorine present, you'll see a green flame come up there.

That definitely contains chlorine, so-

No laser cutting that.

No laser cutting that.

Or burning of any kind really?

Yes.

That controls the laser cutters?

That's it.

Alright.

Camera

Making boxes

You can see these are my little Sudoku test pieces. I was playing around with tiles of different sizes before. I want to make a Sudoku where you put the tiles in places and tangibly play around with it, but I wasn't sure how large the slot should be compared to the tile itself. After playing around, I decided about a 20 mm tile is kind of easy to grip and play with and manipulate, and have a stack of them and not take up too much space. 21 mm pole is easy to get in and out. 3 mm clearance is enough.

Then after playing around with it, I'm actually like, '3 mm is ridiculously large.' 1 mm of clearance is perfectly fine.

You design it on a special app?

Camera

This is Inkscape, which is open source. It's like Adobe Illustrator or something, but it's open source. We output in DXF format and then take it to the machine and import it there. There's a series of rain dance steps that we do. If you do all the steps in the rain dance, then generally your file is intact and you can cut stuff.

That's a lot of fun.

The cool thing about Inkscape though is it actually has a plugin which allows you to do boxes on the fly very quickly, square boxes with partitions, whatever.

Oh, so the software actually allows you to-

Generates the, yeah. Say I want a box that's this wide, this deep, this high-

It'll make it, right?

You can say, 'My material is this thickness,' and it says, 'Would you want that to be your inside or outside dimensions?' Yeah, it makes it ridiculously easy.

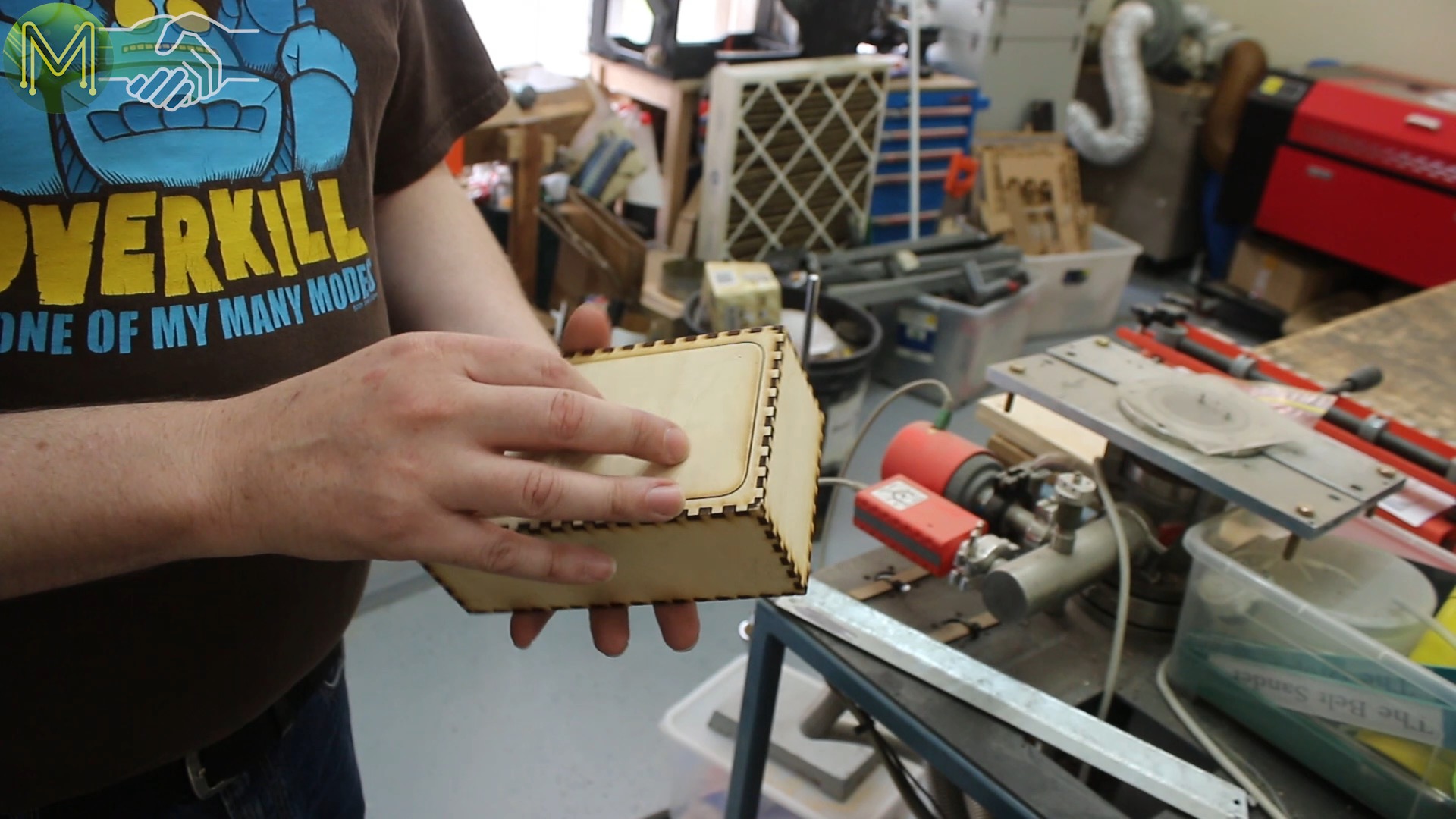

Camera

That is so cool.

All you do to make the box is to just customize it and add the bits that you want. In this case, I added a nice level cutout, so I've got the-

It's a cool box.

Funny you should say that, but carpentry is all about how to make a box.

Yes.

That's all it is.

Totally.

Camera

Carpentry

That's Gavin's current obsession.

Yes, this is my current obsession. This is where I got up to recently.

Nice.

I'm happy with that.

Look at that.

What's that? That's a dovetail or something?

Yeah, that's how I got up to it.

Look how tight that is. What's the name of this joint here?

That's a box joint. Because the laser cuts vertically down, which is always in a straight line, you can't really do dove tails in the same way.

Have you seen biscuits, biscuit joints?

Camera

Getting in trouble at school

My first encounter with biscuits was with Gavin in high school where we-

Ha ha. Oh no! Is this another story is it?

Someone else had joined two bits of wood with a biscuit, and we both determined that we would snap the biscuit. We put both our weight on it and it snapped outside of the biscuit. The deputy principle came and found us, and he told everyone that two bright sparks, I still remember the phrase he used, 'Two bright sparks decided to break this, and they couldn't break the biscuit. They broke it just on the outside to show you how strong it was.'

We were embarrassed to, 'See, we demonstrated something.'

I filtered that out, but I remember that.

Yeah?

Yeah.

Camera

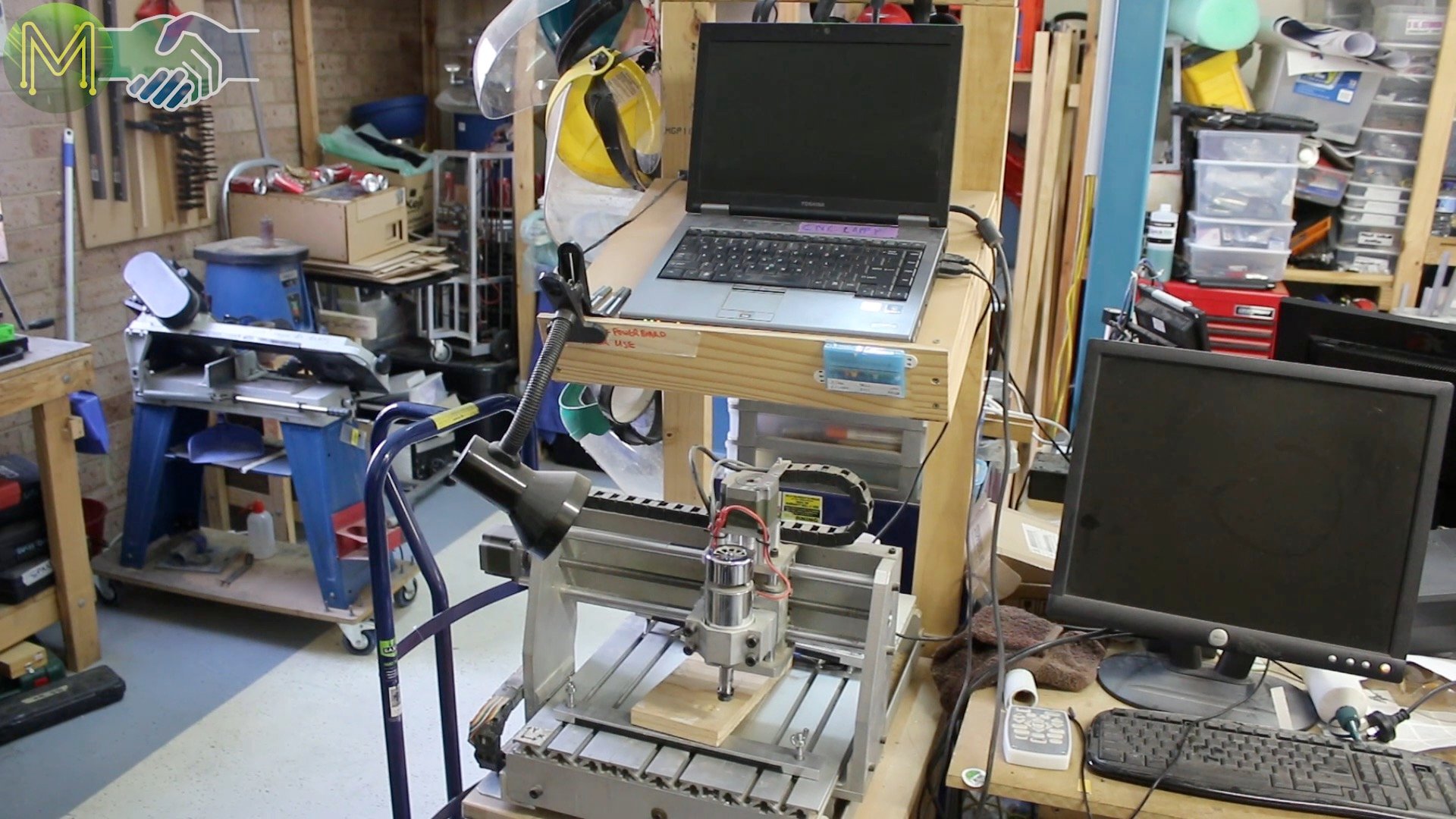

CNC machines

This is our Xcarve. This is a CNC machine. If you program in on a laptop what you want it to do, it'll go and cut it for you. Also, the secret to having any tool in a communal environment is you need to have all the accessories and all tools there and self-enforcing, so that people know they go back in that spot. If it's not obvious, it'll end up everywhere and you'll never have the machine working again.

The spot has to be obvious.

Something resting on the keyboard.

The old dust in the keyboard. Press F3 to remove dust.

That's it.

Do you have any samples of CNC material?

Camera

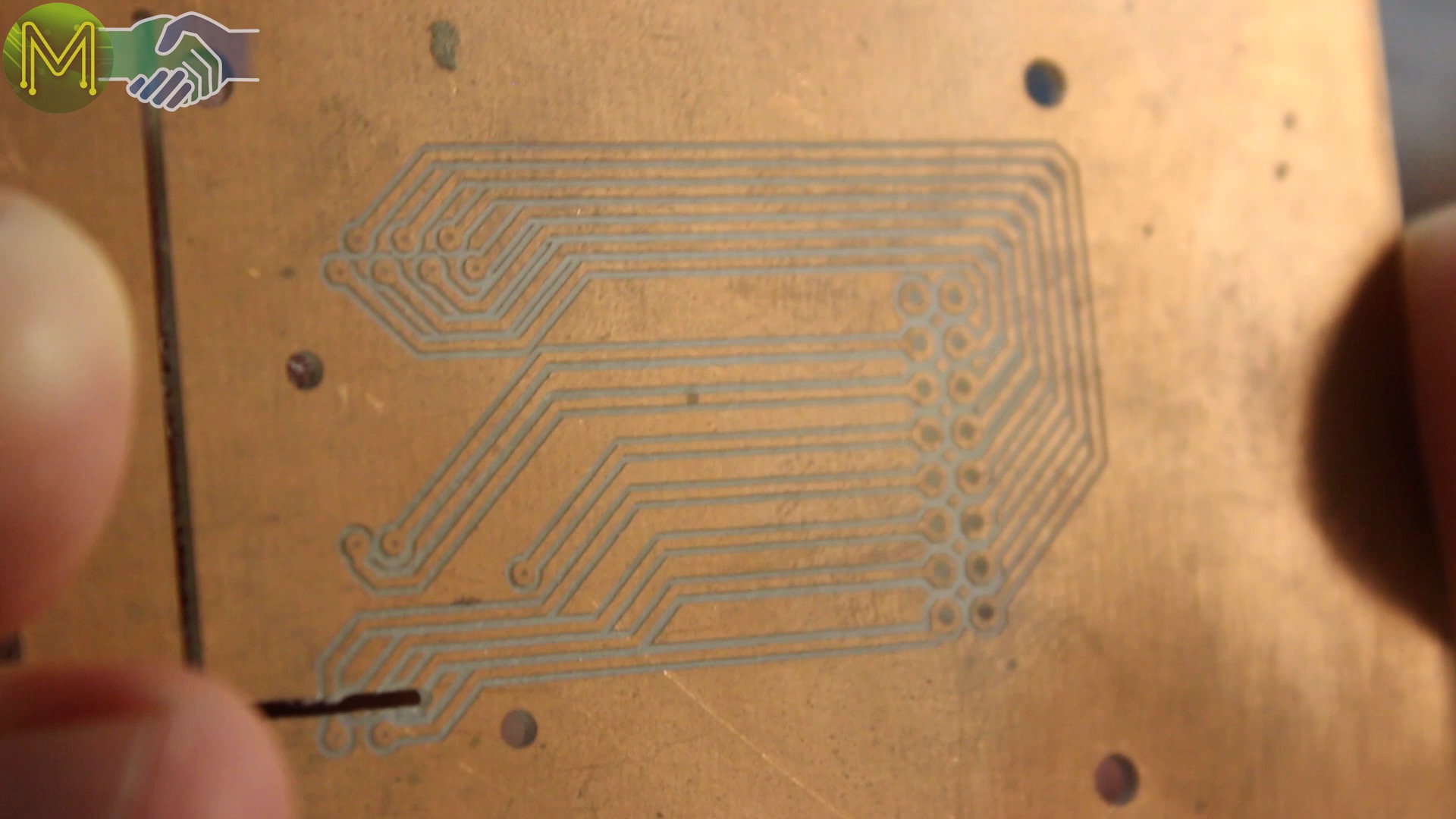

That's the circuit board.

Oh, good old circuit board. Of course, the middle here means you can't laser cut it, so you'd use CNC.

What this is doing is having a v cutter that comes down and just gouges out the groove. Technically you're carving out the Voroni Diagram of the circuit.

So the opposite?

The opposite, yeah. Normally you'd use three tools. You'd use v cutter to cut the actual traces out. You'd use a drill hole to put all the holes for your IC's and internal stuff. Then you'd use a router bit to cut the edge free and make a small circuit board. It's pretty convenient. You can do it in an hour or so, or less.

There's a sweet spot of like, 'Do I just solder up on protoboard?' Then if it's a little more complex, maybe I'll make a custom circuit board on CNC. Then if it's a little bit more complex, I'm gonna send it away to China and have it fabbed for ten dollars, but it's gonna take me three weeks or whatever. There's sweet spots where this machine becomes really useful.

You can draw it in Eagle or standard CAD stuff. There's a script for Eagle called PCB Gcode, and that will take your file and generate the motions of the cutter. To do that you can tell it how wide isolations you want and how deep.

Camera

Hacking vending machines

Zero dollars from every purchase goes to special children.

Have you internet connected it?

One of members is working on that actually.

Alright good, excellent. I'd be surprised if it wasn't.

That's a big topic of discussion.

Camera

Check out Part 2 of this transcript and video.